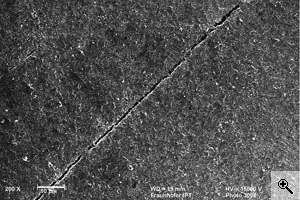

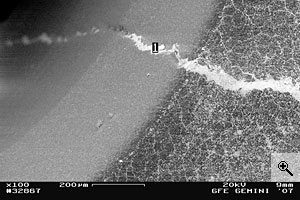

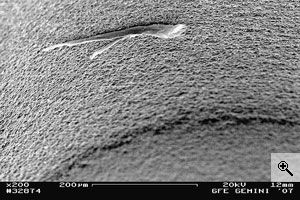

Failure…Failure…Failure…

Since the beginning the wire die manufacturers could detect faulty material with the PCD.

These defects occur during the process of manufacturing (laser drilling, ultrasonic shaping and polishing).

But also while using the PCD tools in the drawing process (breakage of the wire, defect of the die or both).

Defects shown in the pictures on the right are all found in pcd products of well-known manufacturers.